Sodium Dichloroisocyanurate SDIC Powder/Granular/Tablets

- Active chlorine: ≥55% There are two kinds of effective chlorine content of dichlorine in the market: 56% and 60%.

- Moisture content: ≤14

- Solubility (25οC): 25g/100g water

- PH value of 1% solution: 5.5-7.0

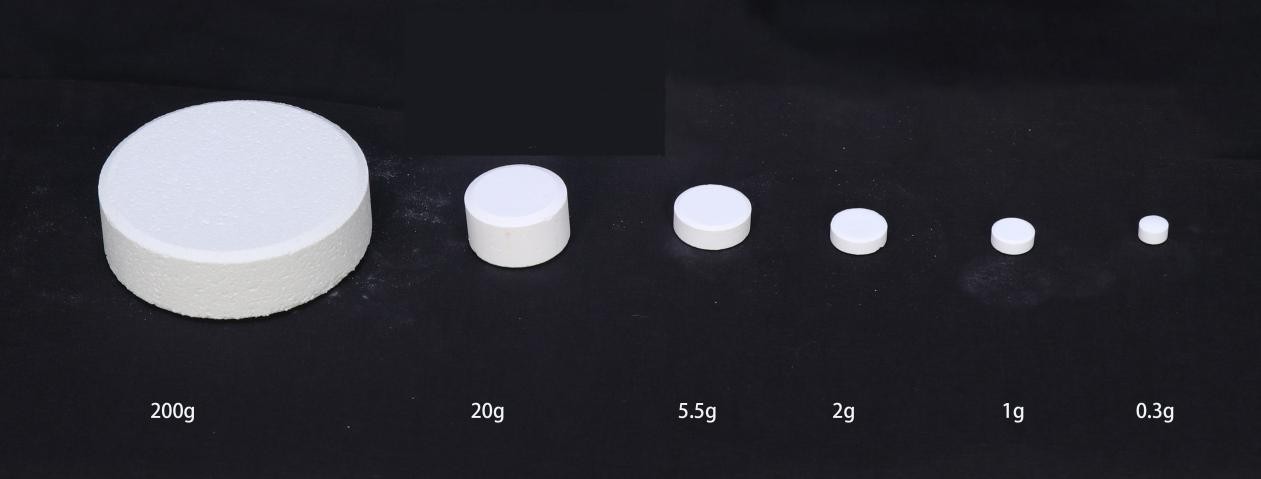

- Specifications: Powder, Granule (8-30mesh, 20-60mesh), Tablets (20g, 5g, 1g). Size of granular and tablets can be customized.

- CAS No: 2893-78-9

- MF: C3O3N3CL2Na

- HS Code: 2933692910

Excellent solubility, high purity, leaves minimal residue, highly effective in effervescent tablet form for quick disinfection.

Product Feature

Strong bactericidal and disinfectant ability, the effective chlorine content of high-quality products is more than 60%, with strong disinfectant and bactericidal effect, the bactericidal rate reaches 99% at 20ppm. It has strong killing effect on all kinds of bacteria, algae, fungi and germs.

- Its toxicity is very low, and it has been approved at home and abroad to use DCCNa in the process of disinfecting and killing food and drinking water.

- Wide range of application, the product can not only be used in food and beverage processing industry and drinking water disinfection, cleaning and disinfection of public places, in the industrial circulating water treatment, civil household sanitation disinfection, disinfection of the breeding industry and other aspects of the wider use.

- High utilisation of effective chlorine, DCCNa has high solubility in water, every 100mL of water can dissolve 30g of DCCNa under 25°C. Even in the water solution where the water temperature is as low as 4°C, DCCNa can release all the effective chlorine contained in it quickly, so that its disinfecting and sterilising effect can be fully utilised. Other solid chlorine-containing products (except for chlorinated isocyanuric acid) have much lower chlorine value than DCCNa due to lower solubility or slow release of chlorine.

- Better stability, due to the higher stability of the triazine ring in the molecule of chlorinated isocyanuric acid products, so the nature of DCCNa is very stable. According to the test, the dry DCCNa stored in the warehouse, after 1 year, the loss of effective chlorine is less than 1%.

The product is solid and can be made into white powder or granule, which is convenient for packing and transporting, and also convenient for users to choose and use.

- Sodium dichloroisocyanurate is more stable than trichloroisocyanurate, releasing less chlorine gas during storage and transportation and emitting a milder odour.

Performance Parameters

Effective chlorine content, %≥ 60 56 |

PH,1%aqueous solution 5.5-7.0 5.5-7.0 |

Particle size Granule(8-30mesh;20-60mesh); Tablets(20g:5g;1g) |

Packaging 25kg/pp bag;1000kg/pp bag;25kg/plastic drum;50kg/plastic drum;50kg/fibre drum. |

Product packaging:

Powder: pure white powder

granular: 5-8 mesh, 8-30 mesh, 30-100 mesh

tablet: 1g, 2g, 3.3g, 20g,200g

drum, bucket, barrel, container

5kg,10kg, 15kg, 25kg, 50kg/ drum

50kg/drum,21mt/20”containe

The Main Application:

Sodium dichloroisocyanurate SDIC is a broad-spectrum disinfectant, sterilizer, and algicidal deodorant. It has the advantages of strong sterilization, good stability, low toxicity, and no pollution. Troclosene sodium can quickly kill viruses, bacteria, and spores that can effectively prevent hepatitis and other infectious diseases. Widely used for drinking water disinfection, preventive disinfection, and environmental disinfection. SDIC chlorine also can be used for silkworm rearing disinfection, livestock, poultry, fish feeding disinfection. In industry, it can also be used for wool shrinkage control finishing, textile industry bleaching, industrial recycling water algae removal, rubber chlorination agent. FOCOUN SDIC is high efficiency, stable performance and no harmful effect on the human body.

Faqs

- Sodium Dichloroisocyanurate (SDIC) is a high-efficiency solid disinfectant with dichloroisocyanuric acid sodium salt as the active component, usually containing 90% available chlorine. It appears as white powder, granules, or tablets, with strong oxidizing and bactericidal properties. It can rapidly kill bacteria, viruses, fungi, and bacterial spores, and decomposes stably in dry conditions, making it a widely used disinfectant in multiple fields.

- Water disinfection: Used for swimming pools, drinking water purification, industrial circulating water, and sewage treatment. 2. Public health: Disinfects environments and surfaces in hospitals, schools, hotels, and public toilets. 3. Aquaculture: Sterilizes fish and shrimp ponds to inhibit pathogenic microorganisms and algae growth. 4. Agriculture: Prevents and controls crop diseases as a fungicide for fruits, vegetables, and grains. 5. Emergency epidemic prevention: Used for environmental and water disinfection in disaster-stricken areas and epidemic sites.

1. By physical form: Powder type (fast dissolution, suitable for large-scale dilution), granular type (easy to measure, for automatic feeding), and tablet type (precise dosage, convenient for daily use). 2. By purity grade: Industrial-grade (for sewage treatment, industrial water) and food-grade (for drinking water, food processing). 3. By application: Water treatment-specific, agricultural-specific, and public health-specific.

- Drinking water disinfection: Add 0.5g SDIC to 1000 liters of water, stir well, and stand for 30 minutes (residual chlorine 0.3-0.5mg/L). 2. Swimming pool disinfection: Add 3-5g SDIC per 100 cubic meters of water, maintain residual chlorine at 0.6-1.0mg/L. 3. Surface disinfection: Dilute 5g SDIC with 10 liters of water, wipe or spray the surface, and air dry after 20 minutes. 4. Aquaculture disinfection: Sprinkle 100-150g SDIC per 1000 cubic meters of pond water, stir evenly, and reapply after 7 days if needed.

- Store in a cool, dry, and well-ventilated place with temperature ≤30℃, avoiding sunlight and moisture. 2. Keep the package sealed tightly to prevent moisture absorption, decomposition, and loss of available chlorine. 3. Store separately from acids, ammonia, organic substances, and reducing agents to avoid dangerous reactions. 4. Keep away from children and pets, and do not store with food, beverages, or feed.

- Raw material reaction: React cyanuric acid with sodium hydroxide and chlorine gas under controlled temperature and pressure to generate SDIC. 2. Purification: Remove impurities through crystallization, filtration, and washing to improve product purity. 3. Forming: Process the purified product into powder, granules, or tablets (add stabilizers and binders for tablets). 4. Quality inspection: Test available chlorine content, solubility, and stability, then package after passing the inspection.

- Personal protection: Wear gloves, goggles, and a mask during operation; avoid direct contact with skin and eyes. Rinse with plenty of water for 15 minutes if contact occurs. 2. Prohibit mixing: Do not mix with acids, ammonia, or organic compounds, as toxic chlorine gas may be produced. 3. Safe operation: Dissolve thoroughly before use; do not use in closed spaces without ventilation. 4. Waste disposal: Dilute unused products with a large amount of water and discharge in accordance with environmental regulations; do not discard directly. 5. Emergency handling: Use dry powder fire extinguishers for fires; do not use water.

Get A Free Quote

- Please feel free to give your inquiry in the form below. Thanks.